Source manufacturer · Customized on demand · Complete specifications · Quality assurance

service hotline400-886-9109

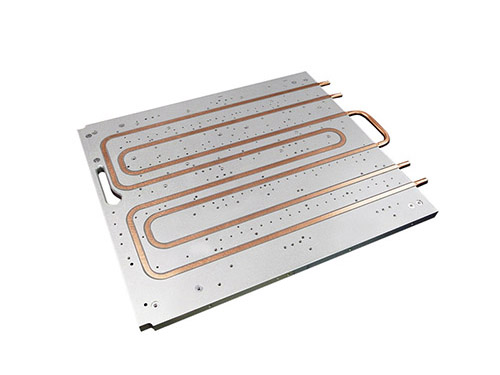

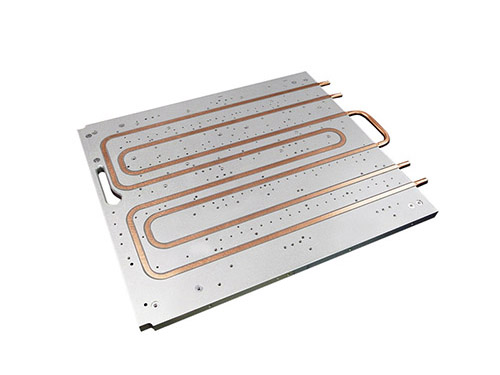

The strict restrictions on the volume and mass of aerospace vehicles such as satellites, spacecraft, aircraft and missiles have promoted the development of cold plate cooling technology for electronic equipment. The cold plate is a single-fluid heat exchanger, often used as the base of electronic equipment. It takes away the consumption of electronic equipment or components installed on it through forced convection of air, water or other refrigerants in the channel. Heat dissipation. For example, on spacecraft, a circulating cooling cold plate system that uses liquid refrigerant is often used to transfer the heat of the electronic equipment to the radiator or the aircraft skin, and then dissipate it into the space where the temperature is absolutely zero. In order to improve the heat dissipation capacity of the cold plate, various high-efficiency fins are often installed in the cold plate channel.

The cold plate has the following characteristics: ① The cold plate is generally made of materials with high thermal conductivity. As long as the components are properly placed, the surface of the cold plate can be close to isothermal, thereby taking away a large concentrated heat load.

②The refrigerant absorbs the heat dissipation of the electronic components through the partition wall. Since the two are not in direct contact, the pollution of the electronic components by the refrigerant can be avoided.

③Since the cold plate adopts indirect cooling, some refrigerants with poor dielectric properties but excellent heat transfer performance, such as water, can be used to improve the cooling efficiency of the cold plate。

④The equivalent diameter of the cold plate channel is small, and the channel can be arranged with various high-efficiency fins, so the heat transfer coefficient of the cold plate surface is high.

Therefore, the cold plate cooling system is more and more widely used in the thermal control of electronic equipment, especially where the power density is high and the volume and quality are strictly limited, the cold plate has special advantages.

follow

Market service department:+86-137-1246-1610

consultation