Source manufacturer · Customized on demand · Complete specifications · Quality assurance

service hotline400-886-9109

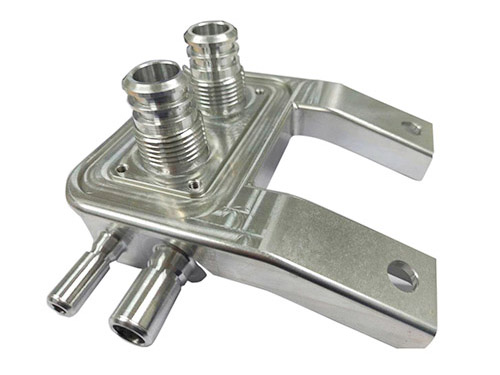

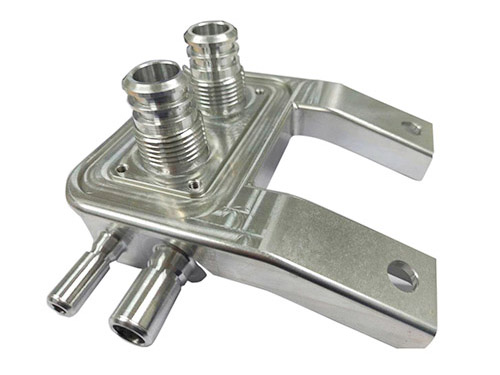

Heat exchanger is an indispensable refrigeration equipment in refrigeration technology. The internal structure of the heat exchanger includes: condenser, evaporator, regenerator and intercooler. The heat exchanger also has many advantages in terms of small size, weight and metal consumption. The application of heat exchanger accounts for more than 50% of the entire refrigeration equipment, and it also has a significant impact on the refrigeration performance. After long-term development, strengthening the heat transfer performance of the refrigeration heat exchanger, reducing the weight and volume of the heat exchanger, and reducing metal consumption have always been the development direction of the refrigeration industry. The new type of heat exchanger adopts a new type of fully welded plate heat exchanger that has been applied to refrigeration technology and has shown great development potential in the application process.

Heat exchangers come in various forms, plates and specifications, but with the same performance, they are all suitable for heat exchange between water and water, steam and low-temperature water, and oil and high-temperature water. The heat exchange equipment used in these circulating media can be said to be one of the high-quality heat exchange equipment with higher heat transfer coefficient, more obvious heat exchange effect, and stronger resource utilization capacity in modern society. As more and more users use heat exchangers, the problem of unsatisfactory heat transfer effects of heat exchangers has become increasingly prominent. Here are the reasons for the unsatisfactory heat transfer effect.

1. Non-standard selection and incomplete consideration of flow: When many users purchase and consult heat exchanger equipment, they only provide the relevant heat exchange area or heat exchange, without considering the circulating medium and its nature, flow, composition and working pressure. It simply considers the heat exchange area of the heat exchanger, while ignoring other requirements. Therefore, either choose a large or a small one. The heat exchanger selected in this way is definitely not suitable and does not meet the normal actual use requirements, which will cause the heat exchange effect to be unsatisfactory during use.

2. The system configuration structure used is unreasonable: the heat exchangers produced by most heat exchanger manufacturers will be designed and configured according to the user's actual use requirements and actual working conditions during the production process. However, in order to save production costs and increase profits, some manufacturers, so that the heat exchanger will only play a role in heat conversion, we can know according to the law of energy conduction, that is, the heat released by the hot side is equal to the heat absorbed by the cold side. For example, the amount of water and water temperature are not enough, causing the hot end temperature to fail to drop. If this is the case, the heat exchanger is useless if it is too large.

3. The manufacturer’s equipment does not meet the standards: Generally, heat exchanger manufacturers will carry out standardized production and design in accordance with the requirements of national standards and industry standards, and pass relevant tests and pressure tests before selling them to users. However, some emerging small-scale manufacturers do not follow formal production procedures and circulation, but design and manufacture by themselves, which will lead to unsatisfactory heat exchange effects.

follow

Market service department:+86-137-1246-1610

consultation